Neomech Machines is a trusted name in the world of wire and cable machinery, delivering innovative, high-performance solutions built for today’s manufacturing needs. With a passion for engineering excellence and a focus on quality, we design machines that combine efficiency, precision, and durability — helping our clients achieve smoother production and

higher output. From wire drawing and annealing to coiling and complete production line setups, every Neomech machine is crafted to

simplify operations and maximize productivity. Our customer-rst approach ensures customized solutions, reliable service, and long-term performance that our clients can count on.

At Neomech, we believe in progress through innovation. We’re not just building machines — we’re building partnerships

that power industries.

Neomech Machines — Engineering the Future of Wire & Cable Manufacturing.

Productivity

Productivity of 3-4 times higher than conventional Indian machines

Manpower

Lower manpower requirement up to 1/10th of Indian machine

Consumption

Lower electrical power consumption up to 50%

Boost

Lower maintenance and operator interference

Company Overview

Our Engineering Department supports customers’ special requests and answers their particular needs and demands.

Our Resident Service Engineers handle new equipment commissioning, customers’ personnel training, and equipment

troubleshooting as well preventive and defective maintenance support. In addition to the demonstration equipment,Neomech

Machines also stocks most commonly used spare parts that are available for immediate delivery. Competent staff supports

our customers in identifying and supplying the required spare parts.

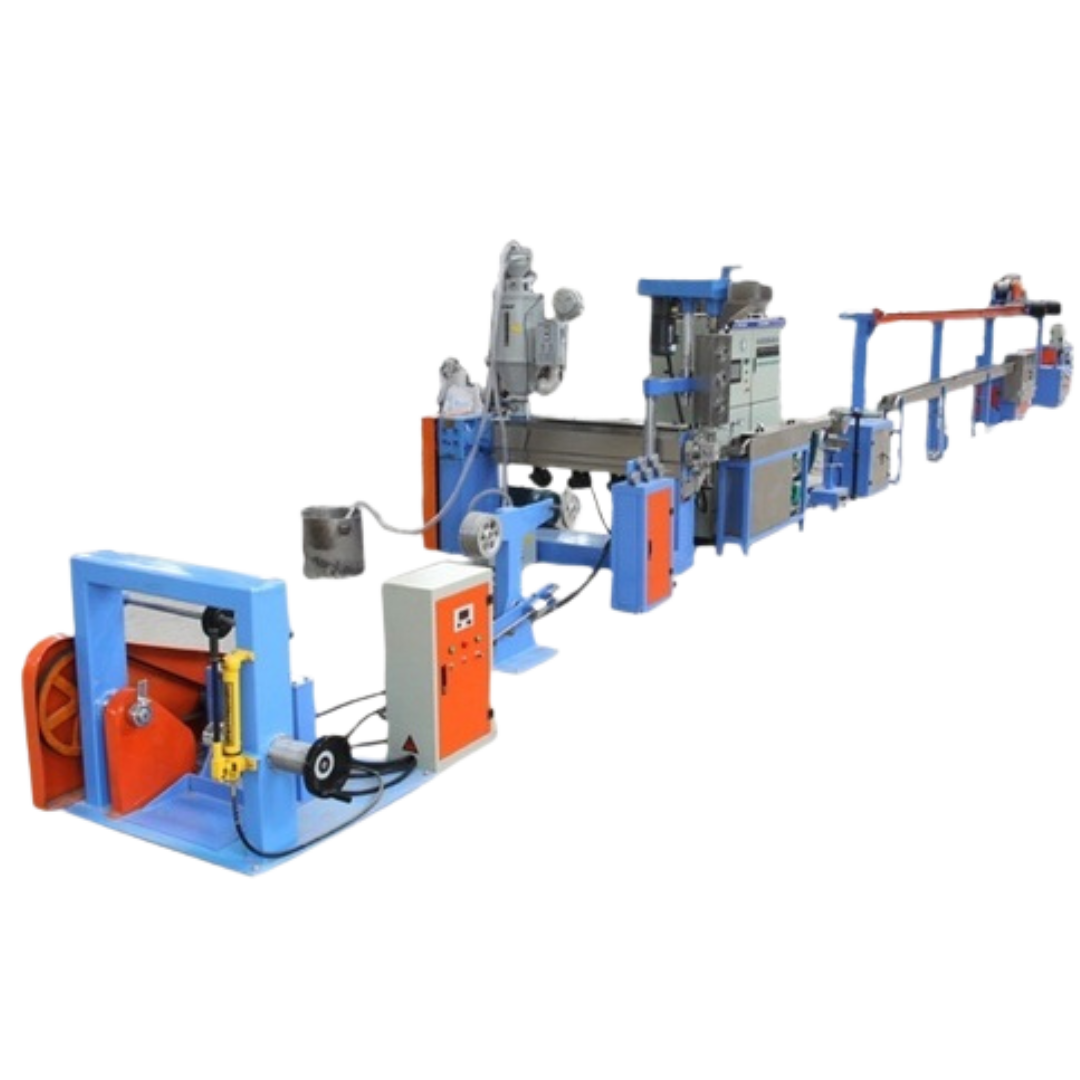

The company’s primary focus is on the integrated machinery necessary to transform raw conductor material into insulated, cabled components ready for final assembly.

1. Extrusion Lines: The Insulation and Sheathing Core

2. Bunching & Laying Machines: Crafting the Conductor

3. Cutting & Stripping Machines: Pre-Assembly Perfection

Neomech Machines operates not just as an equipment supplier, but as a technical resource, aiming to integrate machinery seamlessly into a client’s existing production workflow. By specializing in these three core, interrelated stages of wire and cable manufacturing, the company helps manufacturers achieve.

- Higher Throughput: Faster machine cycles and reduced changeover times.

- Superior Product Quality: Meeting international standards for concentricity, lay consistency, and strip length accuracy.

- Operational Efficiency: Lower energy consumption and reduced material scrap rates.

Crafted for Tough Jobs.

Made for Big Results.

HOW IT WORK

Our Work Process

Lower Production Cost

Our machines are built to minimize energy use, reduce raw material waste, and cut labor dependency. This leads to significantly lower production costs without compromising performance or product consistency.

Innovative Solutions

We offer intelligent automation and fully customized systems tailored to your manufacturing needs. Our forward-thinking approach helps boost productivity and enhance brand value through digital precision.

Zero Reject Targets

Parovi Machines empowers you to reach zero-defect goals with high-accuracy components and built-in quality control systems. Each project is led by experts with deep technical knowledge and field experience.

Low Maintenance Cost

All equipment is designed for easy maintenance and operational stability. With durable parts, smart diagnostics, and full service support, we ensure long machine life and reduced service expenses.

TESTIMONIALS

What Our Clients Say

Optimize Your Wire & Cable Production Today. Get a Free Consultation with Our Experts.

Call Now: +91 8810572318 for Fast Response | Free Consultation | India-Wide Support